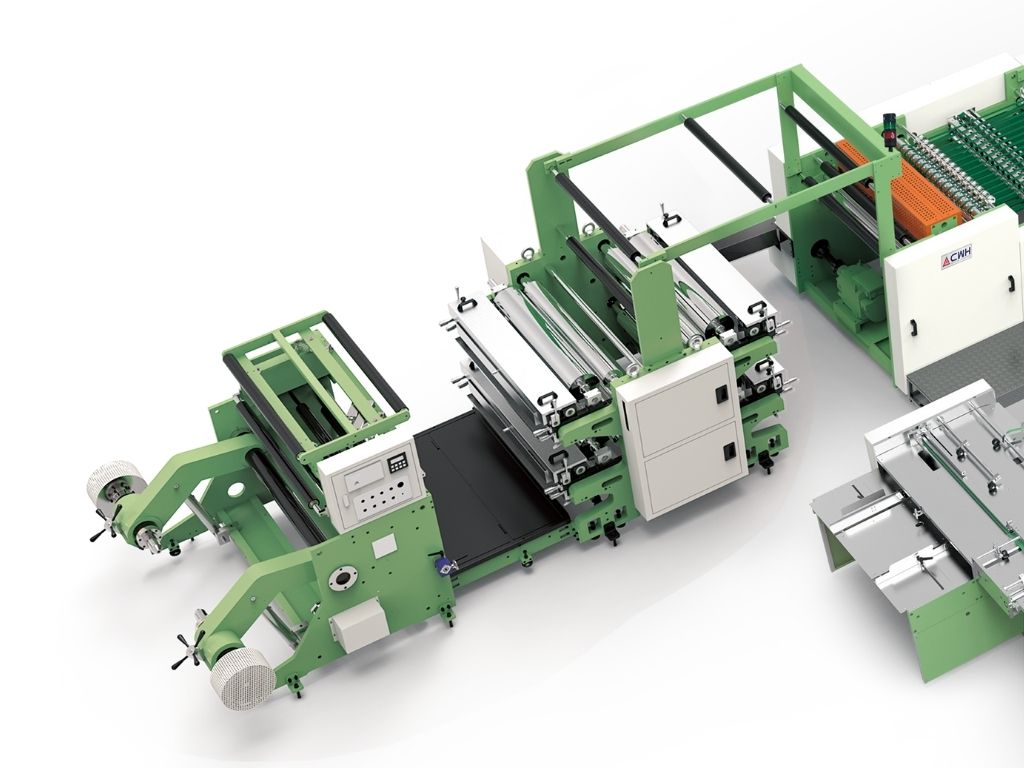

1. Machine Overview

The AFPS-1040PS Multifunctional Automatic Book Production Line For Staple Pin Exercise Books And Sewing Books is a highly versatile and automated production line designed for manufacturing both staple-pin exercise books and sewn books. This machine's front and rear systems are driven by high-power synchronous servo motors, enabling independent or synchronized operation for maximum efficiency. The system is controlled by an advanced motion control system and PLC, which simplifies operation and allows for quick product specification changes via a touchscreen interface without the need for manual gear adjustments. This design enhances automation, reduces production errors, and lowers overall costs by saving clients money and manpower.

2. Key Features and Functions

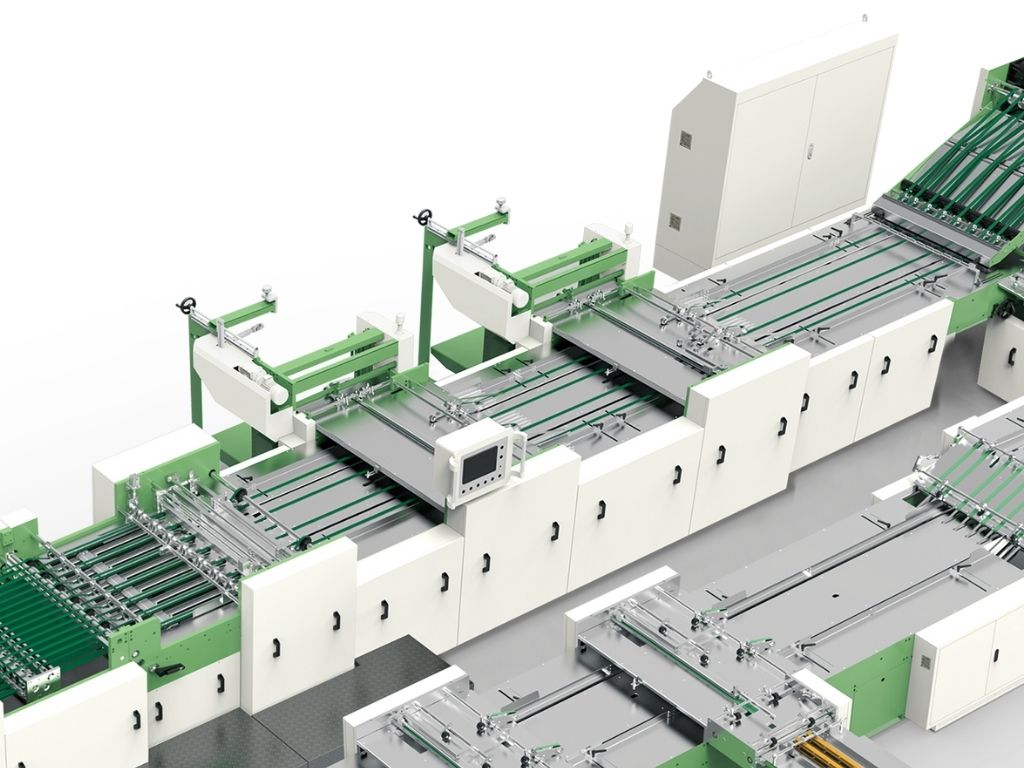

The AFPS-1040PS is a multi-function platform that can be configured for three distinct production modes:

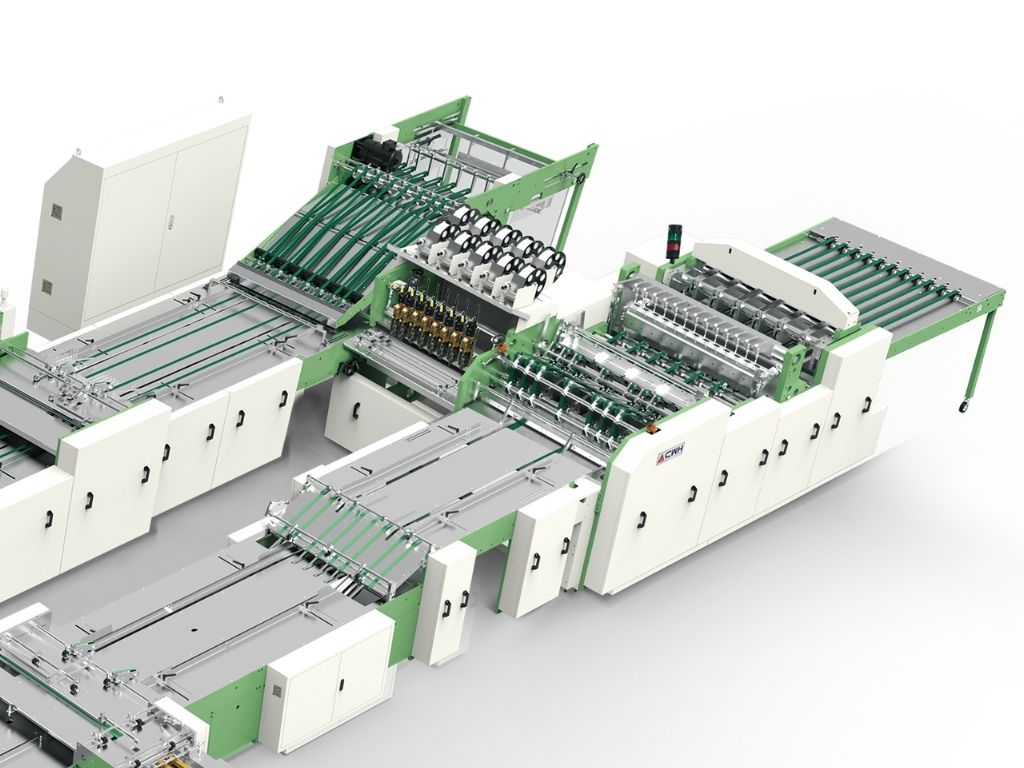

· Staple-Stitching Function

This is a complete workflow for producing staple-pin books, including:

o Reel Unwind Stand: Feeds paper rolls.

o Web-guiding System: Maintain the precise lateral position of a continuously moving.

o Flexo Ruling: Applies ruling and printing paper.

o Cross-Cutting: Cuts paper into sheets.

o Overlapping, Counting, and Collating: Assembles sheets into book blocks.

o Index Page and Cover Feeding: Adds covers and index pages.

o Stitching, Folding, and Back Pressing: Binds and shapes the book.

o Trimming and Delivery: Finishes and delivers the completed product.

· Printing Function

o This mode focuses on producing collated sheets for external binding, ideal for larger or more complex projects. The workflow includes:

o Reel Unwind Stand, Correct System, Flexo Ruling, Cross-Cutting, Overlapping, Counting, and Collating.

o Index Page and Cover Feeding: Adds covers.

o High Pile Delivery: The finished, collated stacks of printed sheets are delivered to a high-pile unit for transport to another binding machine.

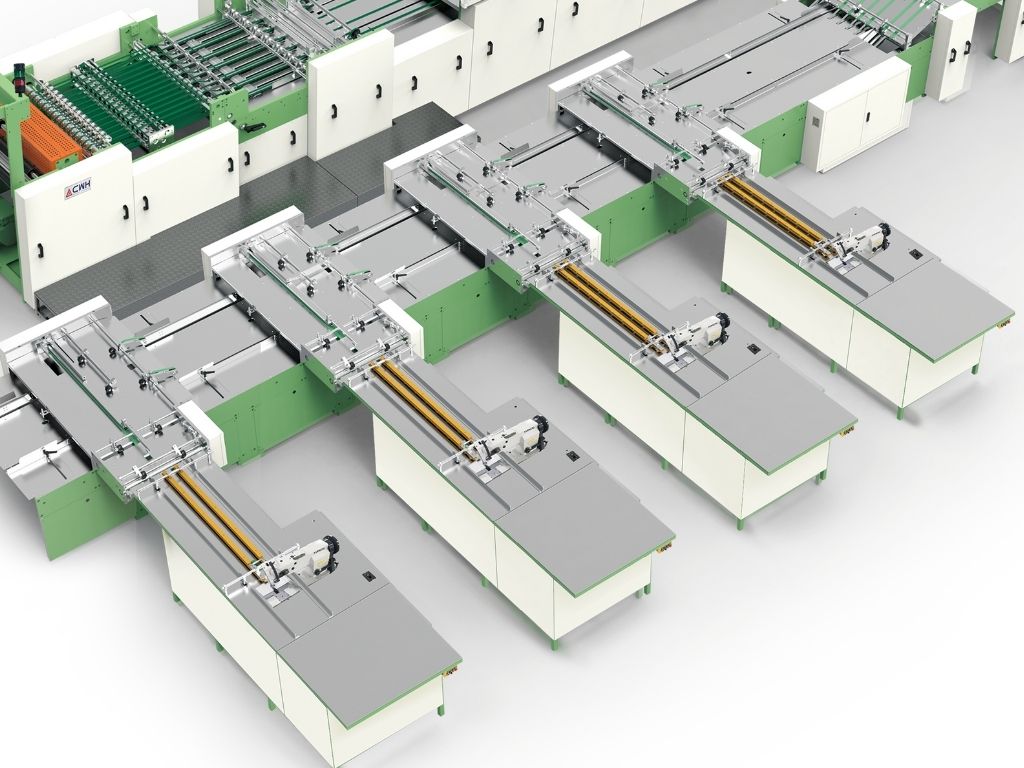

· Sewing Function

o This mode is designed for producing sewn books and includes:

o Manual Bunch Feeding Table: Allows for manual feeding of pre-printed pages.

o Central Thread Sewing: Binds pages with thread for durability.

o Transportation, Folding, Back Pressing, and Trimming: Finishes the sewn book.

o Delivery Table: Delivers the completed product.

3. Benefits

· Multifunctional Capability: A single machine performs three distinct production functions, providing exceptional versatility for different types of book orders.

· Operational Flexibility: The machine's functions can be quickly changed to meet different order requirements, optimizing workflow and reducing idle time.

· High-End Automation: The use of servo motors and a modern control system ensures fully automatic operation, precision, and ease of use.

· Cost and Manpower Savings: This all-in-one solution reduces the need for multiple specialized machines, saving both capital investment and labor.

4. Applications

· Commercial Printing Companies: Ideal for businesses that require high-volume production of educational materials and notebooks.

· Educational Institutions: Suitable for on-demand printing of customized notebooks and exercise books.

· Book and Stationery Manufacturers: Perfect for businesses aiming to optimize their production processes and achieve economies of scale.

Specializing In Manufacturing Of Notebook Machine

Contact

Address: No.5 Baixing Road, BaiHuaDong Village, DaLingShan Town, DongGuan City, GuangDong Province, China

Tel: +86 (0)769 8115 9388

WhatsApp: +852 6760 8288

E-mail:cwh@cheungwohing.com

Service Hotline

+86 0769 8115 9388

Copyright © 2026 Cheung Wo Hing Printing Machinery Co.,Ltd All rights reserved. Website management

Follow us

Monday to Saturday

09:00 – 17:00