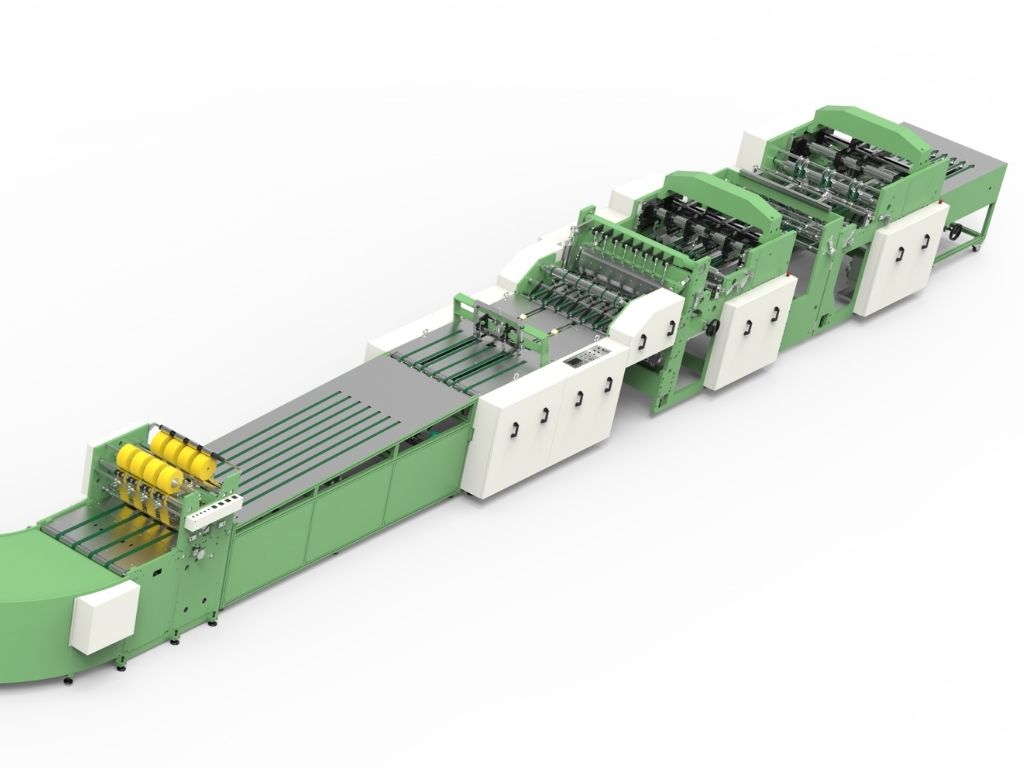

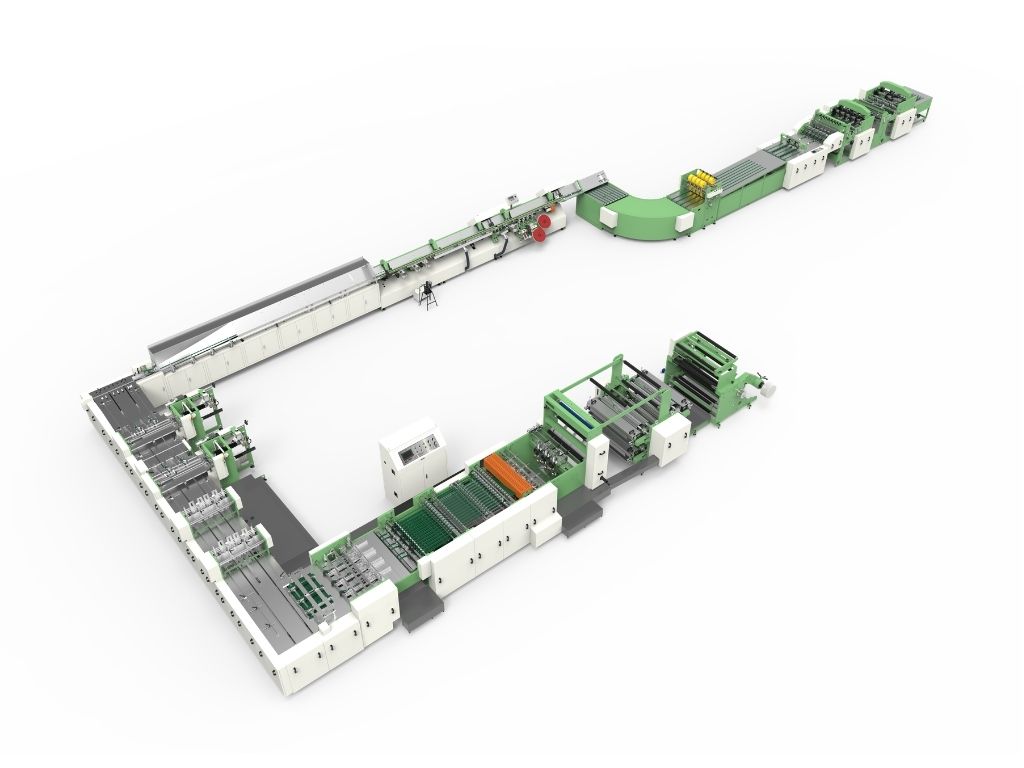

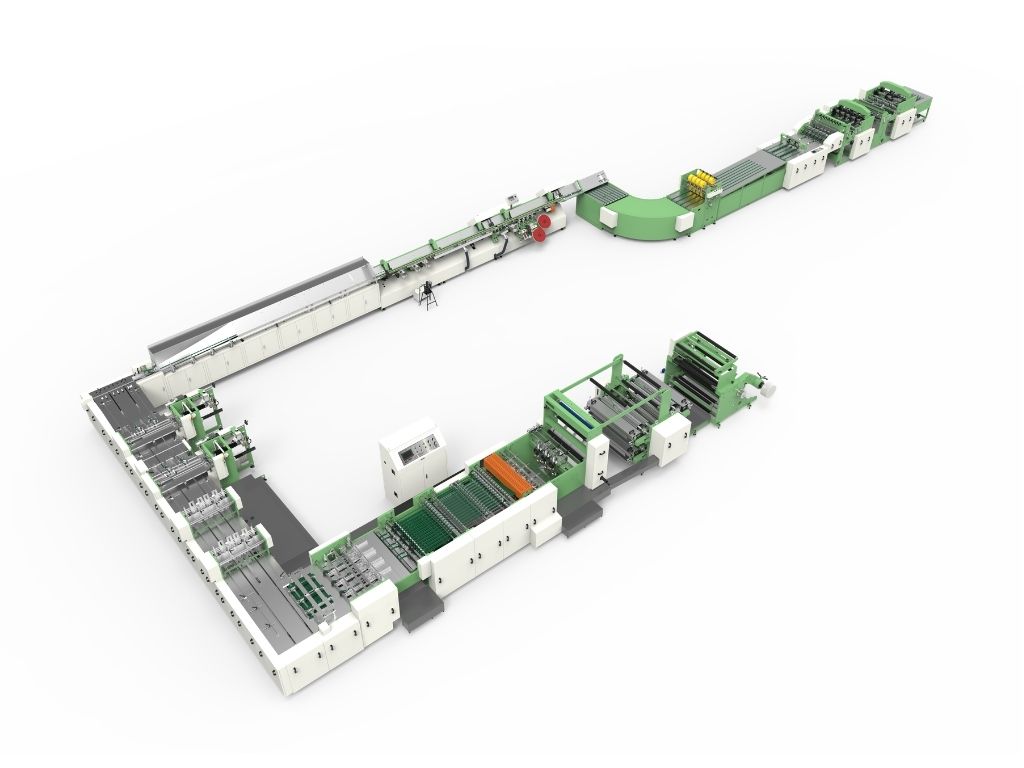

1. Machine Overview

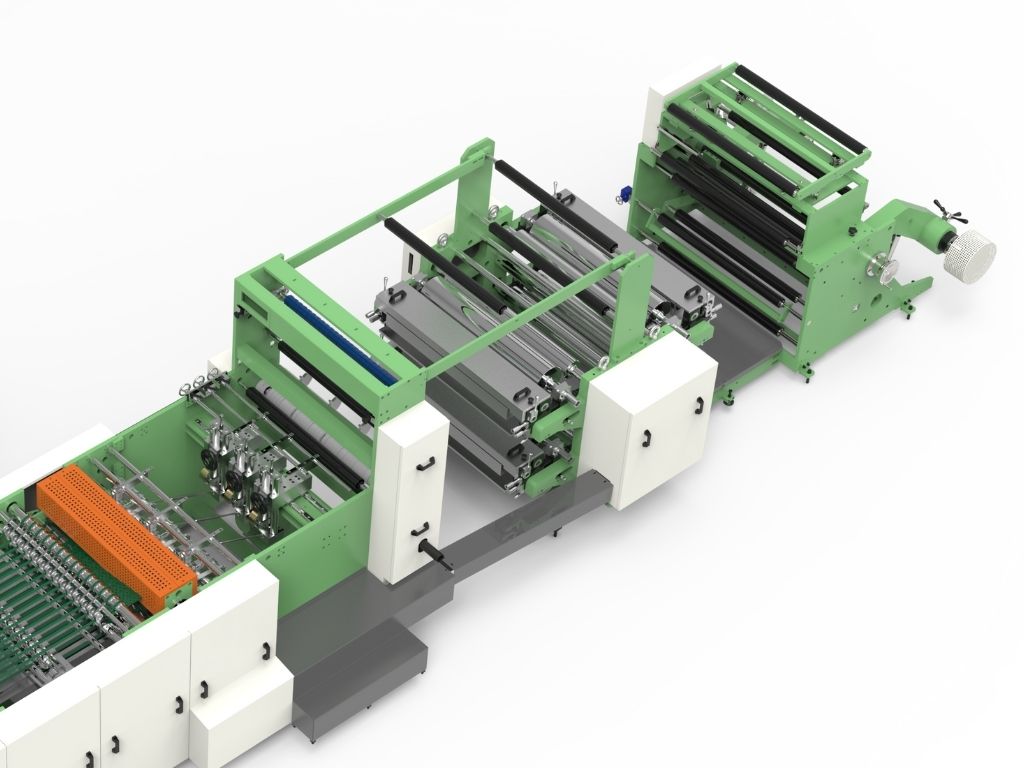

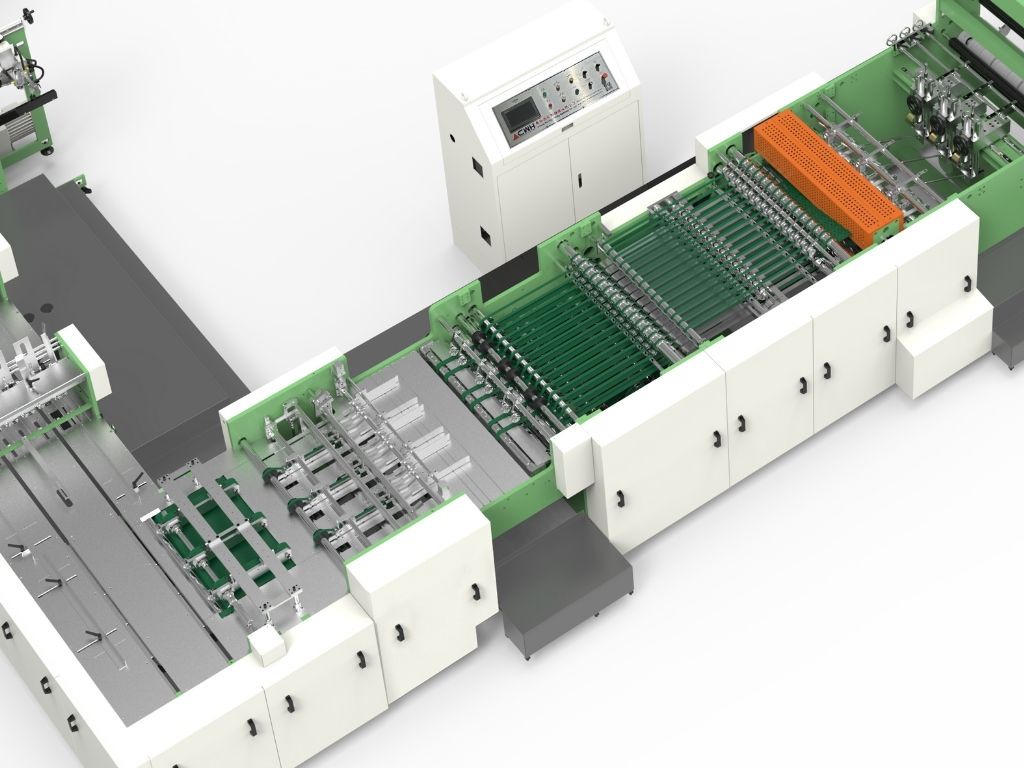

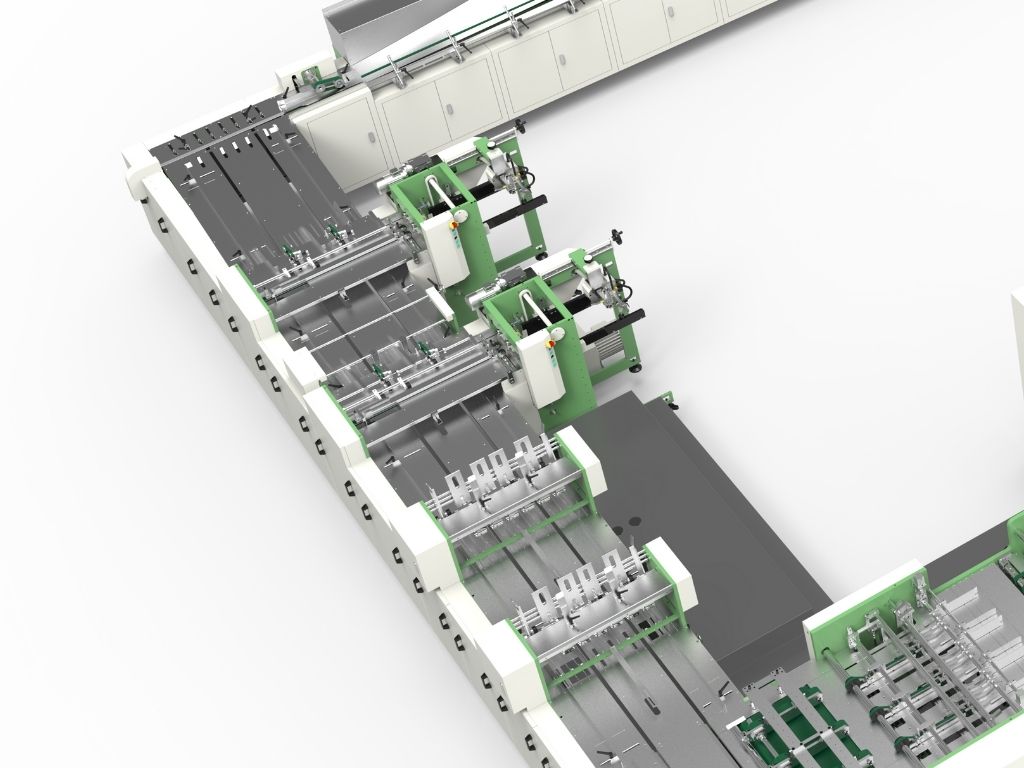

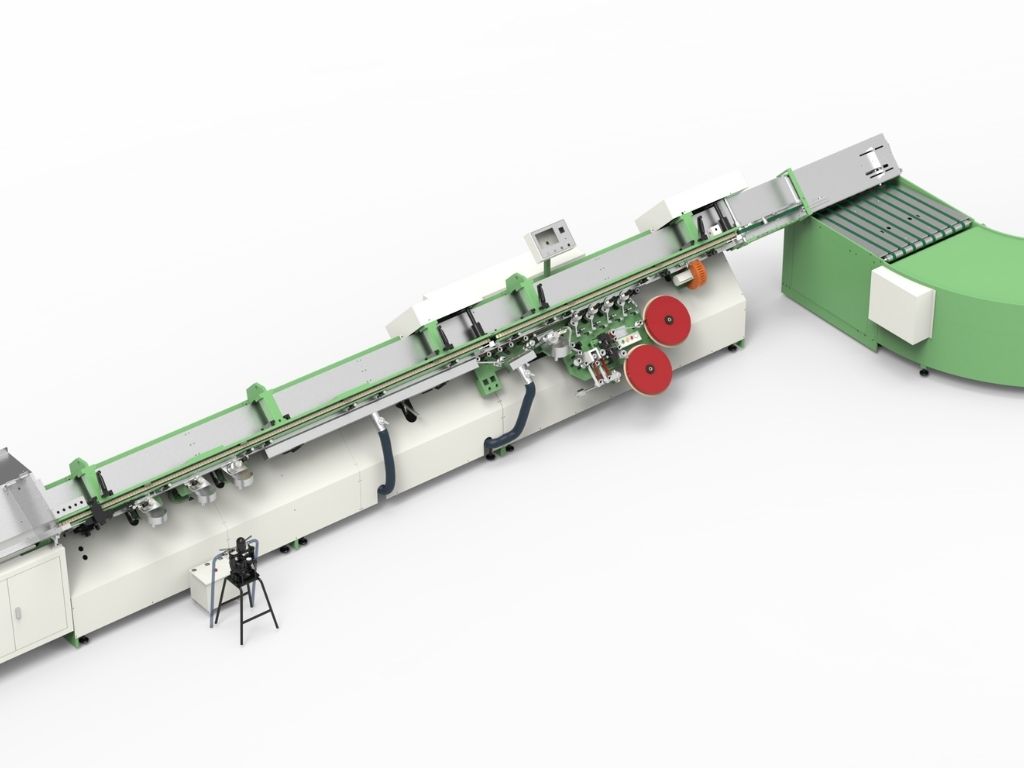

The AFPF-1040C-P2 Glue-Bound Notebook Machine is a non-axis, fully automated production line for manufacturing glue-bound notebooks and exercise books. Developed by CWH, this notebook machine is an ideal solution for producing high-quality, lay-flat books. The system is controlled by a servo motor, PLC, and an advanced electrical control system, which eliminates traditional gear-based adjustments. This high level of automation ensures precise operation, stable mechanical performance, and simplified product specification changes, making it perfect for medium to large production runs.

2. Key Features

· Flexo Ruling Unit (Perfecting 2/2): This unit features a perfecting configuration allowing for one-pass, two-color printing on both sides of the paper (2/2). It includes:

o Circumferential and Lateral Adjustments: For precise control over printing alignment.

o Pneumatic Eccentric Cylinders: Ensures consistent impression and improves overprint accuracy.

o Water-Based Ink Circulation System: Maintains consistent color density.

o Sturdy Construction: Units are framed with thick low-pressure casting alloy steel for durability at high speeds.

· Perforating Unit: This unit uses active feeding to synchronize the paper with the perforating knives. It includes:

o 2 x Micro Perforating Knives: With individual pneumatic pressure adjustment.

o Standard Bearings: Installed into the knife holder for ease of operation, durability, and low-cost maintenance.

· Cover Separation Device: Positioned before the glue application, this device uses mini-cylinders and pneumatic suckers to reliably separate the front and back covers from the inner paper.

· Counting Unit: This unit employs a synchronous servo motor and precision planetary reducers. It allows operators to adjust the sheet count directly via the touch screen, eliminating the need to manually change hanging wheel gears.

3. Benefits

· Fully Automatic and Advanced Design: The machine's non-axis, servo-driven design provides a modern and highly efficient production process.

· High Efficiency and Scalability: Optimized for medium to large production runs, it significantly boosts output and operational efficiency.

· Superior Book Quality: The glue-bound notebooks produced can lie completely flat (180°), which enhances the user writing experience and saves space.

· Operational Simplicity: The advanced electrical control system and touch screen interface simplify product specification changes and reduce setup time.

4. Applications

· Commercial Printing Companies: Ideal for businesses that require high-volume production of educational materials and notebooks.

· Educational Institutions: Suitable for on-demand printing of customized notebooks and exercise books.

· Book and Stationery Manufacturers: Perfect for businesses aiming to optimize their production processes and achieve economies of scale.

Specializing In Manufacturing Of Notebook Machine

Contact

Address: No.5 Baixing Road, BaiHuaDong Village, DaLingShan Town, DongGuan City, GuangDong Province, China

Tel: +86 (0)769 8115 9388

WhatsApp: +852 6760 8288

E-mail:cwh@cheungwohing.com

Service Hotline

+86 0769 8115 9388

Copyright © 2026 Cheung Wo Hing Printing Machinery Co.,Ltd All rights reserved. Website management

Follow us

Monday to Saturday

09:00 – 17:00